First, technical expertise:

The use of photochemical etching technology has changed the traditional way of using metal parts such as cars and punches.

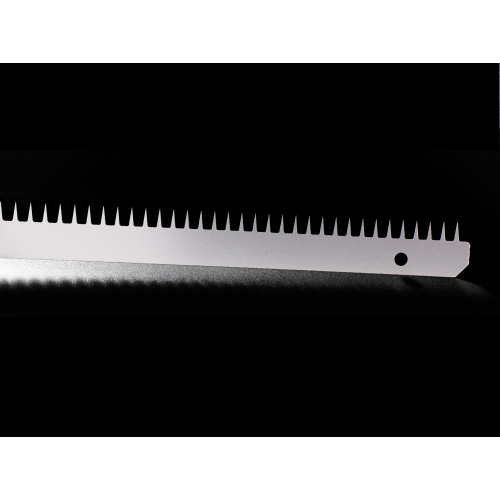

The fine processing of various metals, alloys, and stainless steel flat parts is as large as the large-area microporous filter used in the conventional industrial equipment, and it is almost as small as the eye can hardly distinguish the fine parts.

According to the figure, red and polished metal products with uneven shapes, such as: text, numbers and complex patterns, patterns.

Produce a variety of precision, arbitrary shape through-hole parts.

Second, the product features:

The product has no burr, no bulges, the same light on both sides, and the same level;

No impact on the production process, no deformation, good flatness;

Short production cycle, fast response, no need for mold design, manufacture;

Long life, the entire net made of a flat sheet;

Third, the scope of application:

VCM spring and spacer parts, VCM Zoom, OIS-SMA Accessories, Integrated circuit lead frames, fluorescent screen grids, arrays, various spring parts, mobile phone parts, copper or stainless steel paste leaking version, metal through hole cover plate and various metal frames.

Fourth, technical standards:

The most fine processing line width: 0.02MM

The largest processing area: 500MMX600MM

Material processing thickness: 0.02MM-0.5MM

Graphic positioning accuracy: 0.01MM